In this article

The combined offering enables cost-effective, smart supply chain solutions for food delivery companies

LONDON, UK – July 2nd, 2019 – hoopo, the company redefining geolocation technology with high-accuracy low-power capabilities via the Internet of Things (IoT), and Polymer Logistics, a global leading provider of “One-Touch / Retail Returnable” Packaging (RRP) and pooling services solutions to retailers worldwide, have today announced a partnership to deliver IoT tracking to the supply chain across Europe. The partnership aims to increase product freshness, reduce food waste, and cut costs along the supply chain.

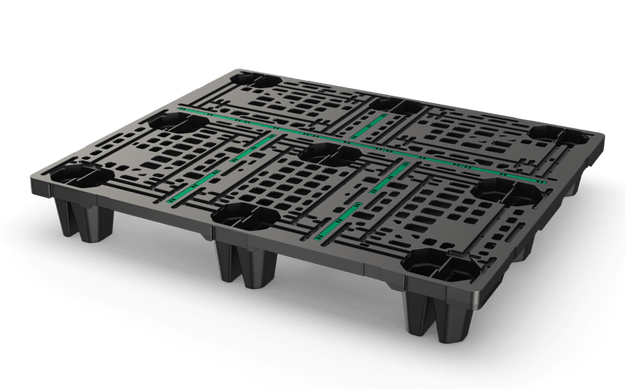

Through the partnership, which began in February 2018, hoopo has designed a bespoke end-to-end IoT tracking device to digitise Polymer’s delivery assets. The device enables Polymer’s European customers to more effectively track and monitor the status of their assets along the supply chain by connecting their pallets and containers to the internet.

The unique geolocation device uses the LoRa communications protocol to enable low-power, wide-area connectivity, meaning it can locate assets without the need for GPS. This maintains the device’s low-power consumption and enables years of battery life, while providing useful intel and data on the assets in real-time.

An initial trial of the technology by a UK leading foodstuff producer has been ongoing since 2018. The company is using the device to track and monitor the status of its cold chain deliveries in the UK. The trial is in its first phase but has already enabled the producer to better understand the delivery routes of its produce as well as any temperature deviations during delivery.

Ittay Hayut, CEO, hoopo, said: “This digital transformation of the supply chain is providing Polymer’s customers with ROI right now. However, our hope is that the business intelligence gleaned by connecting plastic pallets to the internet will also provide data insights that will positively transform the operations of many more businesses in the years to come.”

Following the trial of this LoRa-based IoT tracking device, Polymer and hoopo are seeking to improve the functionality of the device to extend its range. This will include ensuring that the device can provide information following periods when it is offline, as well as adding cellular connectivity to offer full supply-chain visibility.

“Too many companies lack information about the status of their assets along increasingly growing supply chains. This is leading to a huge amount of food and financial waste,” said Ohad Perry, CTO, Polymer Logistics. “We aim to provide visibility for the hundreds of thousands of foodstuff assets in the supply chain, from fruit and vegetable boxes to pallets, cages and more by digitising delivery. The combination of our offering with hoopo’s will enable perishable goods producers and retail companies to make much smarter, data-driven decisions that can help reduce cycle-times as well as loss-rates of both assets and goods.”