Corrugated is crushing your supply chain efficiency. Are reusables the solution?

In this article

Every supply chain leader in the food industry is currently facing similar challenges: Rising costs, higher food recalls, labor shortages, sustainability mandates, and stricter regulations.

A recent survey by RELEX Solutions and Researchscape underscores this. According to the study, 60% of companies are fundamentally altering their supply chains to deal with ongoing economic unpredictability.

Yet, packaging—the thing that touches every product that moves through your supply chain—is still an afterthought. Given its potential impact, businesses should reconsider its role.

The real impact of packaging failures in your supply chain

Packaging affects far more than just how products are transported.

It’s why some shipments arrive intact while others don’t, why workers spend hours dealing with box failures instead of stocking shelves, and a significant factor in logistics costs, compliance risks, and sustainability goals.

More specifically, these problems touch areas of the supply chain like:

Product loss from box failures

Moisture exposure weakens boxes, causing them to collapse under stacking pressure. That means rejected loads, wasted product, and more time spent dealing with reorders. For some industries, this can lead to significantly higher shrink rates than necessary.

Unnecessary labor costs

Every single-use box has to be assembled, broken down, and hauled to the baler, pulling workers away from more valuable tasks like stocking and order fulfillment. These inefficiencies compound over time, adding substantial operational costs.

With workforce shortages affecting 76% of supply chains—and 37% reporting significant deficits in transportation and warehousing roles—wasted labor is more expensive than ever.

Wasted truck space and wasted products

Boxes don’t stack efficiently, leading to partially loaded trucks, more trips, and higher fuel costs. Inefficient transport leads to unnecessary emissions and higher per-unit shipping costs. Improper stacking can also lead to product damage and shrink.

Traceability gaps

When a recall occurs, traditional packaging does not provide tracking capabilities, making it harder to locate and isolate affected products. Without clear tracking, recalls tend to be broader than necessary, leading to excessive waste and financial loss.

Shorter shelf life for fresh goods

Perishability is one of the biggest challenges in food supply chains. Reusable packaging containers (RPCs) can extend the shelf life of fresh produce compared to single-use packaging, reducing waste and increasing sales opportunities.

Landfill waste

Millions of tons of corrugated packaging are thrown out every year. Companies facing increasing pressure from regulatory bodies and consumer expectations need solutions that don’t contribute to mounting waste problems.

These problems hit some industries harder than others.

Food safety and biosecurity

The egg industry, already under strain from avian flu outbreaks, is facing heightened scrutiny regarding biosecurity. Any contamination issue can lead to product recalls, lost revenue, and damaged consumer confidence.

Meanwhile, fresh produce, cheese, and meat suppliers are also navigating tighter food safety regulations and increasing transportation costs. When margins are tight, packaging failures add yet another layer of risk.

Strengthening your supply chain: 5 benefits of reusable packaging

Packaging failures shouldn’t be routine. It should do its job: protect products, move them efficiently through the supply chain, and eliminate waste.

Single-use packaging has its limitations.. It breaks down under pressure, creating extra work and adding risk at every stage—but reusable packaging removes those weak points.

Cut product shrink and reduce rejected shipments

Shrink is an expensive, frustrating problem. And each pallet that arrives with damaged goods wastes time, money, and effort.

RPCs solve this with a stronger design that holds up under pressure, preventing box crush and keeping perishable goods fresh longer.

For high-risk items like eggs, meat, and produce, that means fewer rejections, fewer write-offs, and fewer headaches.

Use the labor time for more high-value activities

Single-use boxes create extra work at every step. Workers spend time unloading shipments, cutting boxes open, flattening them, and hauling them off to be baled.

With reusable packaging, there’s no assembly or disposal. Workers focus on stocking shelves and moving inventory instead of dealing with piles of empty boxes.

Companies that switch to reusable packaging reduce store-level labor inefficiencies by more than 50%.

Pack smarter, ship more, spend less

Cardboard boxes limit the amount of product shipped in a single load. They weaken under pressure and don’t stack efficiently, so workers must source extra stabilizing materials or lower stack heights to prevent collapse.

That means more trucks on the road, more fuel used, and more costs passed along the supply chain.

On the other hand, reusables stack neatly and securely, reducing the number of shipments needed. That directly translates to lower transportation costs and fewer inefficiencies in distribution.

Companies that switch to RPCs see up to a 25% reduction in transportation costs.

Traceability that works: Be recall-ready and compliant

Food safety regulations like the Food Safety Modernization Act Section 204(d) require better traceability. However, the old-school methods of manual, paper-based tracking lead to gaps, and these gaps slow down response times when a recall happens.

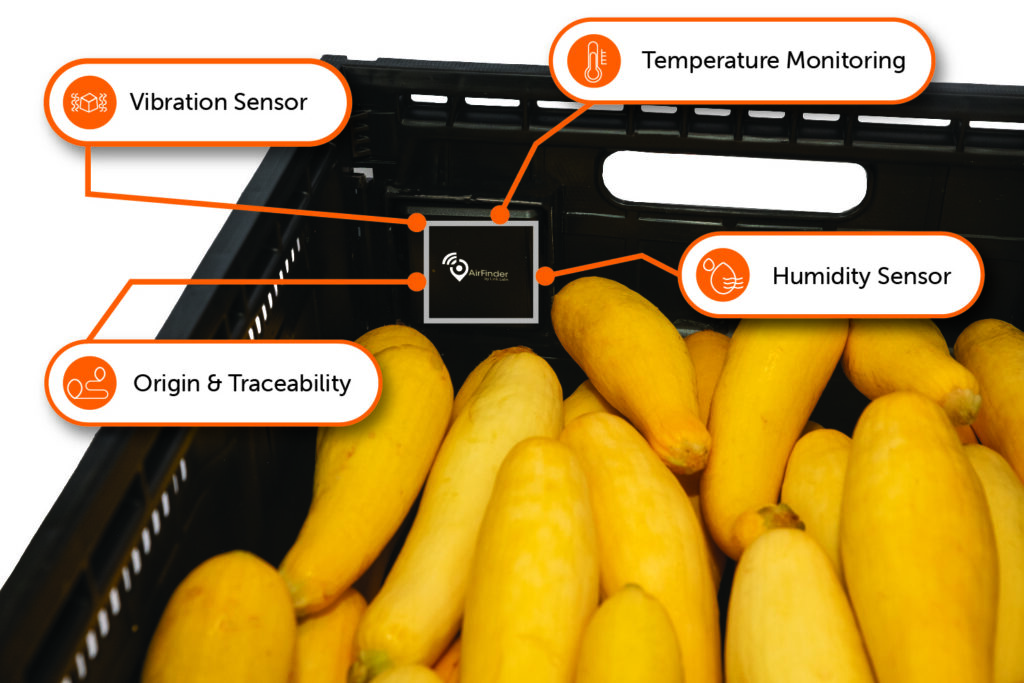

IoT-enabled reusables (like Tosca Asset IQ™) eliminate those blind spots. With built-in tracking, supply chain teams can see where each shipment has been, how long it was there, how it was handled, and where it needs to go next.

According to the International Trade Center, implementing traceability technology can reduce the scope of a recall by up to 95%.

Sustainability that improves efficiency and saves money

Every time a reusable crate replaces a corrugated box, it eliminates waste, reduces landfill contributions, and cuts CO₂ emissions by reducing the number of trucks needed on the road. It also lasts for years, keeping materials in circulation instead of creating a constant cycle of production and disposal.

Tosca’s reusables cut carbon emissions by 66% compared to corrugated packaging.

For supply chains, that means hitting sustainability targets without adding complexity or costs to operations.

Traditional packaging isn’t helping your supply chain

But making the switch to reusable packaging is easier than you might think.

With the right partner, you can test reusable solutions in your supply chain before fully committing. You’ll see the difference firsthand—stronger product protection, streamlined logistics, and measurable cost savings.

Tosca makes it simple:

- Risk-free pilot programs to prove the value in your supply chain.

- On-site research and development, support, and analysis to maximize savings and efficiency.

- Fully managed pooling solutions so you never have to worry about tracking, cleaning, or inventory management.

Your supply chain is only as strong as the packaging that moves it. Are you ready to stop wasting time, labor, and resources on single-use solutions?